I do it two different ways.

For the purfling that will show on the sides, I glue it to the binding using Titebond II. I have a bunch of the little black clamps with orange jaws, and I clamp the entire strip, setting the clamps almost right next to each other. I use Titebond II for this because it's water resistant, so when I go to bend the binding/purfling, I can spritz it with as much water as I need during bending, and I don't have to worry about the binding/purfling separating when bending. When I used regular Titebond, this was a frequent problem.

I like to leave the binding and purfling a bit wider than final width, so that after the glue has dried, I can pass the pieces through my drum sander and sand the purfling and binding flush with each other.

For the purfling that shows on the guitar's back, I cut a stairstep channel for the binding and purfling. I install the binding first. Then I use a 1mm flat graver, which matches the width of my purfling, and scrape the glue residue out of the purfling channel. I apply some Titebond to the purfling channel, thinned with a little bit of water, and press the purfling into the channel, then tape down as necessary. I find that it is much easier to get tightly mitred corners this way than trying to glue the purfling to the binding first.

Best,

MichaelMichael McBroom38864.4529976852

|

I "tack" them with CA...on a sheet of waxed paper...a little accelerant on the purfling, and CA on the binding...just enough time to hold it all flat while the CA kicks...a dab every 4" or so...then when it goes on the guitar it all gets a good CA'ing! (PS. I still plan to meet up with you sometime! The daughter graduates tonite, and then things'll calm down...hope you haven't sold those sandbags!).

I "tack" them with CA...on a sheet of waxed paper...a little accelerant on the purfling, and CA on the binding...just enough time to hold it all flat while the CA kicks...a dab every 4" or so...then when it goes on the guitar it all gets a good CA'ing! (PS. I still plan to meet up with you sometime! The daughter graduates tonite, and then things'll calm down...hope you haven't sold those sandbags!).

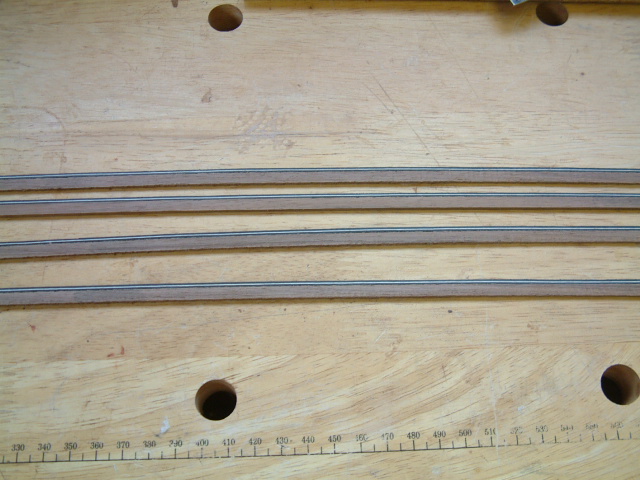

). These are a different st of bindings than the first pictures:

). These are a different st of bindings than the first pictures: